How do Haygain hay steamers work? Find out how simple, safe and effective it is to purify hay. Learn all the components, step-by-step operation, and some of our #steamteam secrets.

Which are the components of Haygain?

Let’s find out in detail what the components of Haygain hay steamers are:

– Boiler (PB model included with HG 600 and HG 2000 and Jiffy model with HG One)

– Boiler – hay box connection pipe

– Hay box (capacity of 8/10 kg for HG One, 15/18 kg for HG 600 and 35/40 kg for HG 2000)

– Aluminum plate with perforated steam spikes (inside the hay box)

Operation of Steamers

How do hay steamers work? Discover Haygain’s patented step-by-step simplicity:

◦ Fill the boiler with water (4 liters with the Jiffy Boiler and 8 liters for the PB Boiler)

◦ Connect the water heater to the electrical outlet

◦ Connect the boiler to the hay box.

◦ Fill the caisson with hay.

◦ Optional: lightly baling the hay can optimize the cycle. In this way, the steam will have less way to disperse inside the caisson.

◦ Optional: lightly wetting the top of the hay can flush out the water with the coarsest layer of dust before the purification cycle.

◦ Close the lid

◦ Start the cycle by pressing the ON button.

◦ Wait at least 60 minutes for optimal and guaranteed purification

◦ During the purification cycle, the steam, thanks to the aluminum plates (a perfect material that helps keep the temperature high without dissipating heat), comes out of the perforated spikes, making a path from the inside to the outside extracting the powders, purifying and hydrating the hay, without cooking it but sterilizing it thanks to the high temperatures.

Some of Haygain’s secrets

Let’s discover together some of the secrets of Haygain Steamers that help make it a must-have product in the stable.

◦ Steam intervenes in the purification of hay but also contributes to its hydration. A small amount of steam escapes from the tangle of hay fibers and reaches the walls of the caisson, condensing and exiting through the hole at the base of the caisson. The rest of the steam nourishes and hydrates the hay, making it softer and enhancing its nutritional properties. The purification cycle does not wash away the nutritional components of the hay but only intervenes in reducing sugars, which are harmful to horses prone to laminitis or prone to metabolic syndromes.

◦ During the purification cycle, there is no pressure inside the caisson thanks to special seals that self-adjust to release the right amount of steam when and if needed. There are also holes underneath the caisson to prevent any risk.

◦ The entire Haygain range is made of composite materials with high-efficiency thermal properties. Even if 100 °C is exceeded inside the container, the outside remains warm to the touch and averts any risk of scalding.

◦ The water heater must always be filled with water to prevent the coils from running dry by overheating and burning (N.B. In spite of everything, there is no danger of explosion but only of wear and tear and breakage of the water heater!)

◦ An excellent management tip is to use timers that can be plugged directly into the outlet. These accessories allow the purifier to be managed remotely or analogically via app and operated at preferred times, saving time and/or money through time slots with lower energy costs.

◦ It is advisable to let the hay cool after the purification cycle for a few minutes; time to empty the box and bring it to the horse and it will be ready for feeding.

◦ Steamed hay has no expiration date. Absent is the use of water, soaking and, therefore, fermentation leading to intestinal damage. Therefore, hay can also be administered 24-48 h after treatment.

◦ A consequent food for thought to the last advice may be related to the size of the purifier to be purchased. It is useful to save on purification cycles by purchasing a larger purifier given the validity of the hay (with one horse, HG One might be advisable because of its small capacity, but purifying with HG600 each cycle can ensure Steamed hay for at least 2 days, saving on purification cycles and stable management)

We all know that steam, when it reaches certain temperatures, is capable of killing bacteria, mites and molds that are harmful to humans. Why not use this powerful and natural resource for our horses as well?

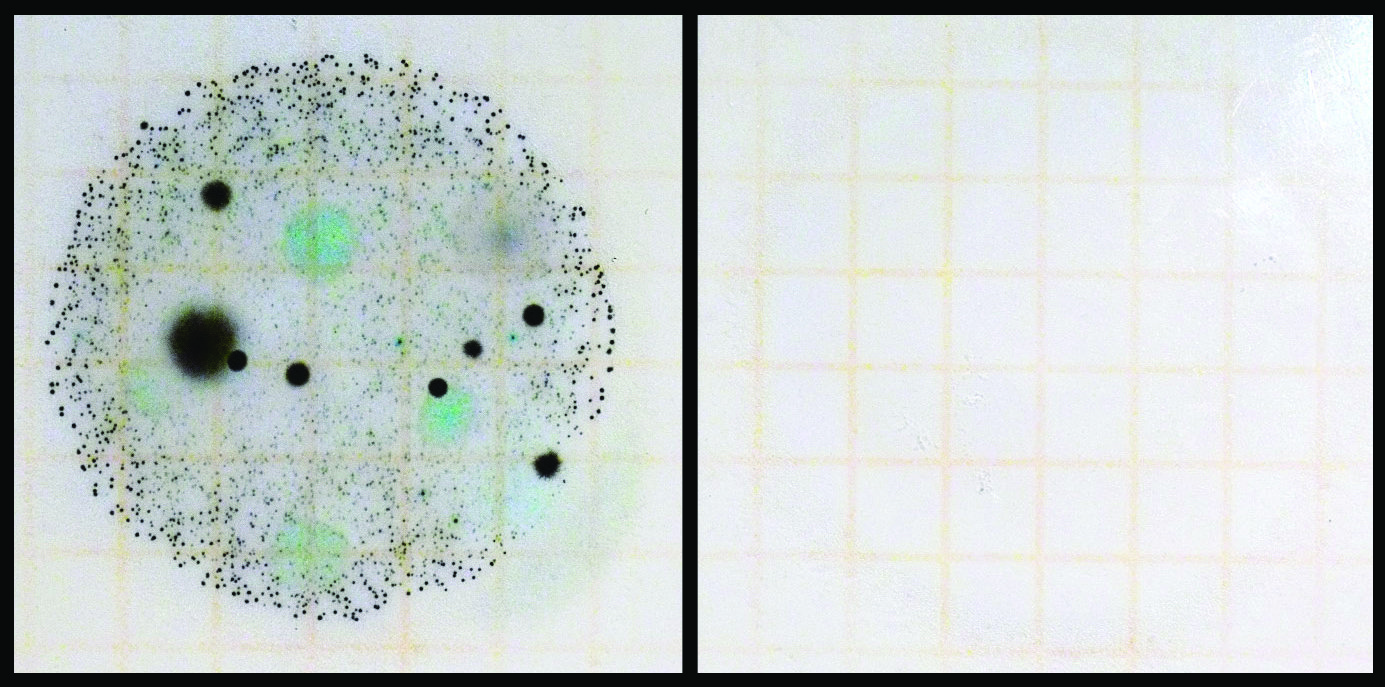

Haygain steamers introduce steam into the hay evenly, reducing respirable dust, spores and mold by 99 percent, as you can see from the image of this tube.

“I don’t need Haygain, I can vaporize hay through do-it-yourself procedures.”

Nothing could be more wrong! Scientific research has shown that to successfully eliminate dust, mold and bacteria, the purification apparatus MUST have an insulated double chest; a simple bin does not insulate the vapor, which as it is lost through the walls does not diffuse evenly. The result? a bin incubator of pathogenic bacteria, mold, and fungi, and a lot of wasted time. SOLO Haygain features a patented steam distribution system through a five-pronged manifold that purifies the hay evenly, reaching a temperature of 100 C° in as little as 60 minutes